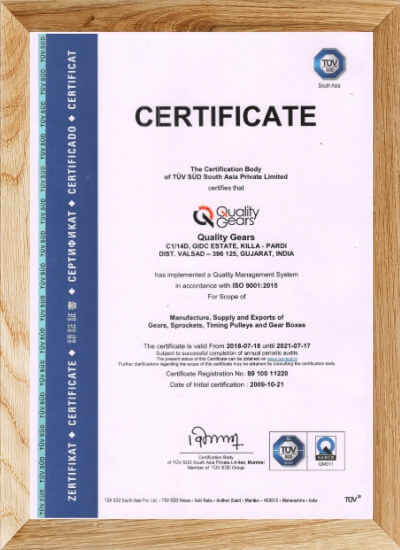

We take Quality very seriously when it comes to our product. A reason why we take pride in calling ourselves “Quality Gears” is because we focus on quality first. With more than 30 years of experience in gear manufacturing we have invested fair amount in keeping our quality in check through these years. Here is a brief introduction to our quality control equipment.

- PCD Concentricity Tester

- Lead and Profile Testing

- Roll Testers for Spur, Bevel and Worm-wheel Sets

- Lead Measuring Machine

- 3D CMM

- Surface Treatment Thickness Checker

- Gauges - Plain Plug/Ring Gauges; Spline Gauges; Thread Gauges

Apart from quality-centric, we believe in system dependent processes. Therefore, we have given special emphasis on investing in a system where traceability of raw material and finished goods is easily done.

At every step of our raw material procurement, we carry out physical and chemical check for material properties to maintain quality of each of our finished goods. Unique identification number is assigned to our raw material and jobs for traceability and their material test certificates, quality inspection is carried out at every step of the process. These data are preserved on job cards and documented for 100% traceability.

Our quality inspection includes a 3-step approval process for any part produced on the floor.

First Article Inspection

In Process Inspection

Final Inspection

Reach Us

-

C1/14D, GIDC Estate,

KILLA-PARDI 396125,

Dist.-Valsad, Gujarat, India -

E : sales@qualitygears.net

E : info@qualitygears.net -

M : +91 - 98251 19835

M : +91 - 99789 19834

© Quality Gears. Designed By :

Softyoug Solutions

Softyoug Solutions